Scope

Material forming and shaping through plastic deformation is one of the most efficient and economical families of manufacturing processes available. The International Conference on Numerical Methods for Industrial Forming Processes (NUMIFORM) has been the premier forum for exchanging groundbreaking ideas and advancing the state-of-the-art in numerical simulations of material forming processes since its inception in 1982.

Building on the success of previous conferences, NUMIFORM 2027 will gather the field’s top experts to discuss the latest achievements, explore future directions, and strengthen professional networks.

About Conference

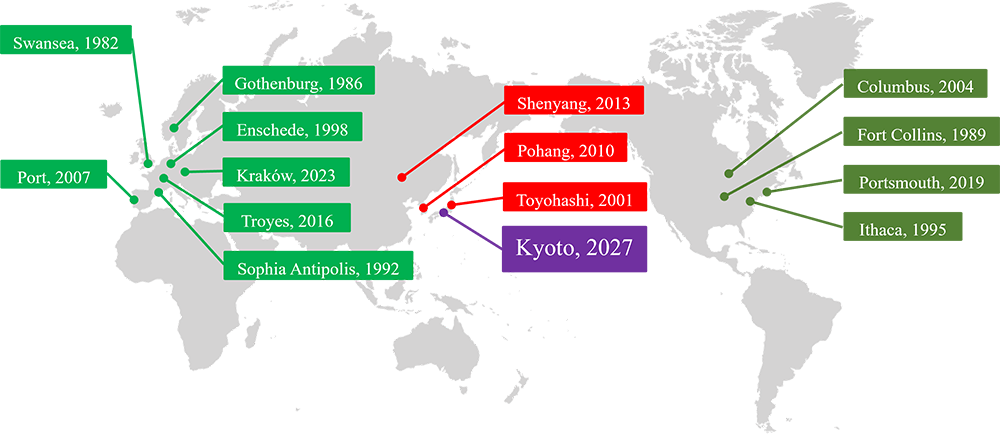

The International Conference on Numerical Methods in Industrial Forming Processes (NUMIFORM) was started in 1982 by the late Professor O.C. Zienkiewicz at Swansea (United Kingdom). Since then, NUMIFORM has been held every three/four years in Europe, North America, and Asia. The previous NUMIFORM conferences were held at Gothenburg (Sweden, 1986), Fort Collins (USA, 1989), Sophia Antipolis (France, 1992), Ithaca (USA, 1995), Enschede (Netherlands, 1998), Toyohashi (Japan, 2001), Columbus (USA, 2004), Porto (Portugal, 2007), Pohang (Korea, 2010), Shenyang (China, 2013), Troyes (France, 2016), Portsmouth (USA, 2019) and Kraków (Poland, 2023). The NUMIFORM 2027 will be held in Kyoto, Japan, on June 14–18, 2027.

- 1982: Swansea, UK

- 1986: Gothenburg, Sweden

- 1989: Fort Collins, USA

- 1992: Sophia Antipolis, France

- 1995: Ithaca, USA

- 1998: Enschede, The Netherlands

- 2001: Toyohashi, Japan

- 2004: Columbus, USAForesight support systems (FSS)

- 2007: Porto, Portugal

- 2010: Pohang, Korea

- 2013: Shenyang, China

- 2016: Troyes, France

- 2019: Portsmouth, USA

- 2023: Kraków, Poland

Conference topics

The Conference aims to provide a forum for academics, researchers, and engineers to discuss and disseminate recent advances and innovations in numerical methods for material forming and shaping through plastic deformation. Conference themes include, but are not limited to, the following categories:

Material Behavior and Modeling and its Numerical Implementation

- Multiaxial plasticity. Anisotropic yield functions and constitutive modeling

- Microstructure evolution and characterization during material forming

- Physics-based modeling of inelastic deformation phenomena, crystal plasticity

- Formability, fracture and failure. Damage and defect modeling

- Tribology. Modeling of contact with friction

Process Modeling and its Numerical Implementation

- Recent modeling methods such as meshless, Arbitrary Lagrangian-Eulerian, Smooth-Particle Hydrodynamics, etc.

- Computational methods in modeling and designing of forming and joining processes

- Implementation of numerical schemes on high-performance platforms, e.g., GPUs.

Conventional and Novel Methods of Forming and Joining

- Bulk, sheet and tube forming

- Casting

- Joining, Welding and friction-stir processing

- Polymer, composite, and powder processing

- Machining

- Microforming

Applications of Data-Driven Science to Forming and Joining

- Applications of Artificial/Bayesian Neural Network and Deep Learning

- Development of surrogate models

- Inverse methods for material identification, Data Assimilation

- Process optimization